Biotechnology Incubators and Facility Inventory

Biotechnology incubators have been helping science progress by building communities, hosting educational events, assisting with compliance, operations, and reducing costs such as having shared equipment. At a basic level, a biotechnology incubator is a shared facility where smaller companies work alongside each in a shared facility. In this post, we will explore two compliance complications that can occur at these facilities. The first is related to maintaining safety data sheets (SDSs) and the second is monitoring the total volume of flammable chemicals. These requirements can be enforced by OSHA, EPA, and fire departments.

If you are a current tenant or evaluating a shared facility it’s worth asking what the incubator’s policies are regarding compliance with OSHA, EPA, and fire department violations and possible fines. Incubators often have policies that compliance including fines will be applied to the tenant if there is a violation. Ideally, this is clearly explained in your lease agreement, but we’re finding that is not always the case. The reason is that the building owner may be the one fined and they will in turn try to collect the funds from the tenant.

The facility can be fined for tenant errors, reference, “As a building owner or manager, you may find yourself on the receiving end of an OSHA citation, even though the employees at risk from an unsafe working condition are not yours but those of a tenant or contractor… If OSHA determines that the incident was caused by the owner’s or employer’s negligence or misconduct—that is, he or she was aware of the hazard but did not abate it—the agency can impose fines as high as $70,000 for each violation, for each day that the violation existed, and for each employee affected. In addition to monetary fines, criminal prosecution may also be imposed on the owner.” Since as a tenant you could be held liable here are some questions worth asking the incubator.

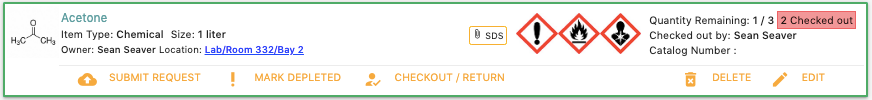

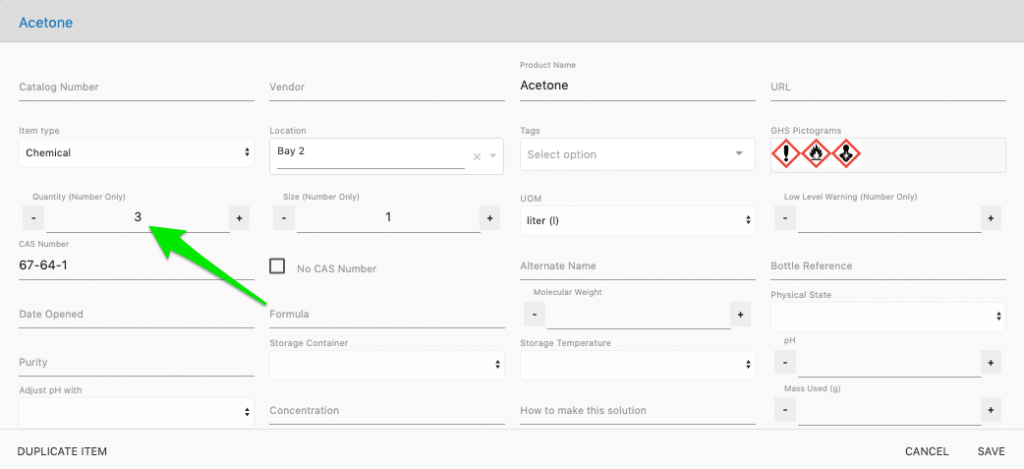

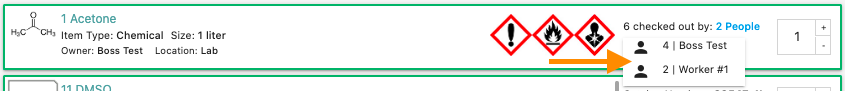

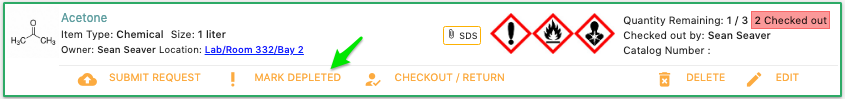

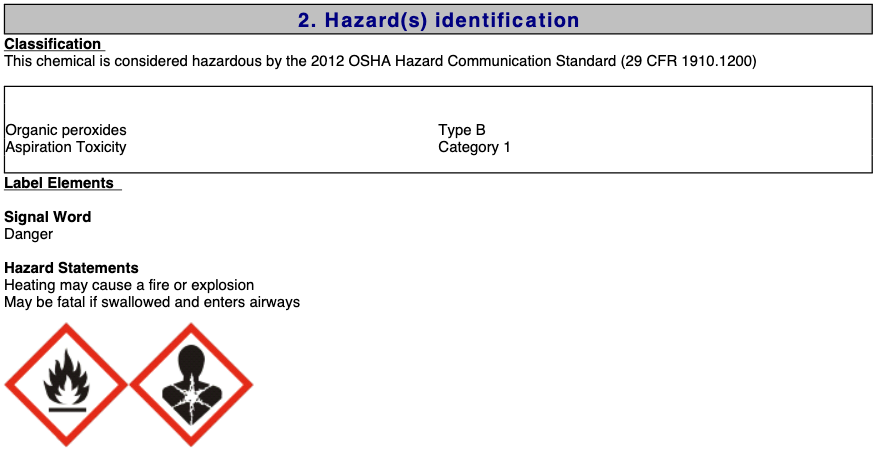

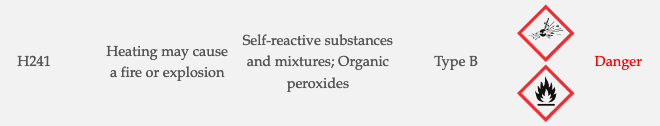

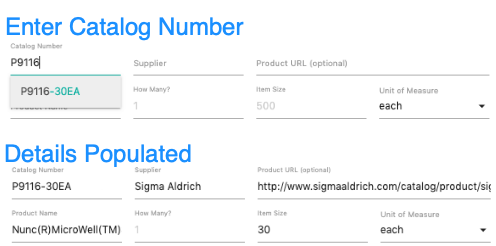

When OSHA does an inspection and wants to know if all the SDSs are present, are they? What is the procedure to the ensure these documents are accurate and correctly maintained? Often incubators are request SDSs from tenants on an annual basis, but this is not in compliance. The reason is that SDSs are required to be maintained for each item as it enters the facility.

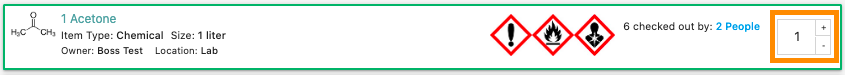

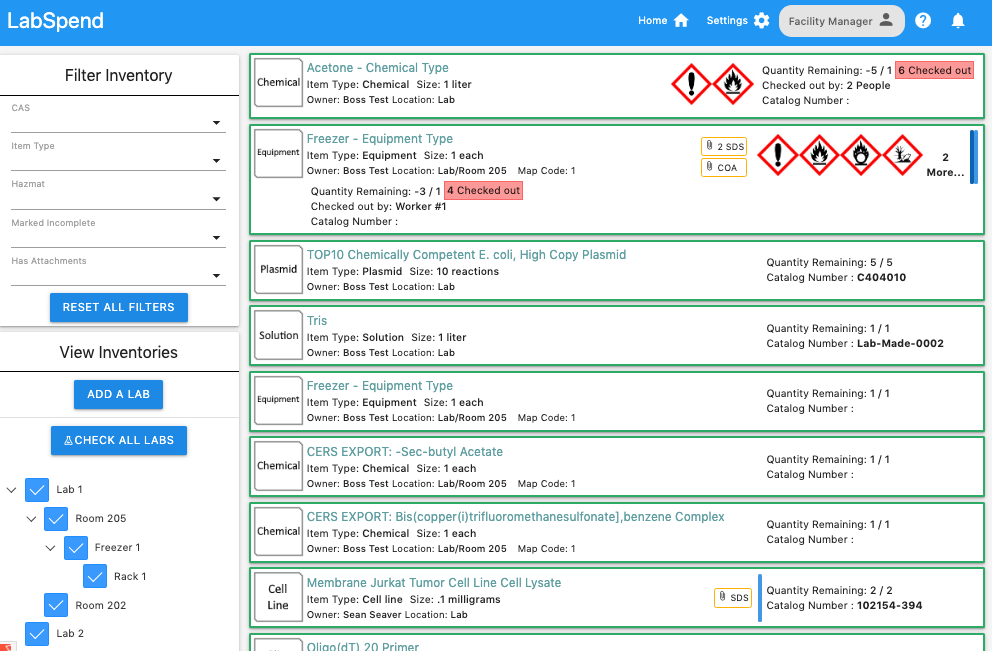

When the fire department does an inspection, who is responsible for monitoring the total volume of flammables in the facility? How are tenants kept aware of the total volume of flammables? If the total volume is exceeded how is the violation assessed?

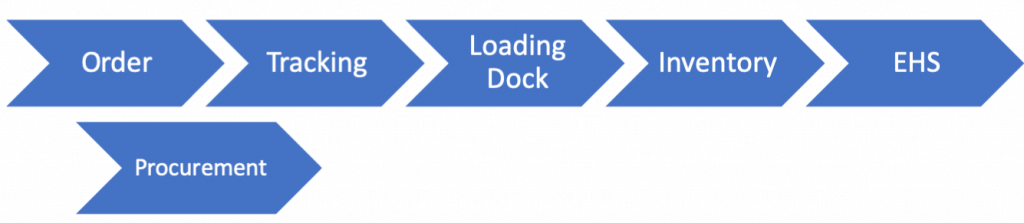

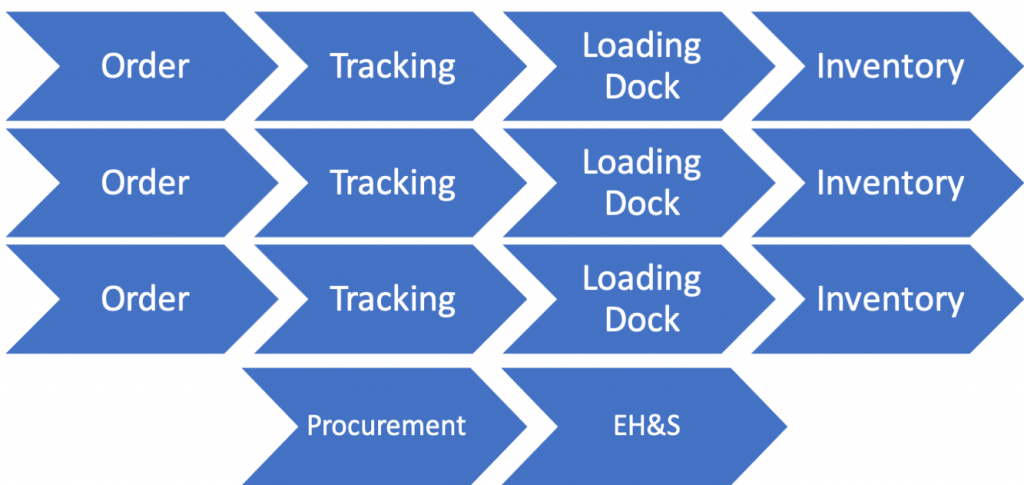

Often each tenant company is ordering the products needed for their research, but don’t know the current flammable volumes in the facility.

Since facilities are often not monitoring what is entering their buildings and tenants don’t know what each other have on-site it creates a compliance nightmare. Although tenants according to their leases are held liable for compliance violations, it is very difficult for them to even know if they are in violation. The reason being is that tenants or facilities do not have a method of viewing inventories. We’ve found that many incubators don’t have these policies clearly outlined and are relying on the fire department not to enforce the issue. These are challenging problems that our company, Lab Spend will continue to tackle by developing free lab inventory software for both incubators and individual labs.